The RP133 Garage Door Threshold Seal is suitable for all types of garage doors.

NOTE: Prior to installation, the concrete floor surface must be cleaned thoroughly to remove dust, oil and grease. If the floor is painted, wire brushing where the seal is to be installed will ensure best adhesion. (A good quality caulking gun is required for adhesive supplied) Prior to step 8, roll out RP133 to lay flat preferably in sunlight until RP133 is level along full length. Apply suitable weights to hold RP133 flat along full length in step 9. Please refer to the door manufacturers door closer adjustment instructions before installing the RP133 threshold seal. Manual door close latching may require adjustment.

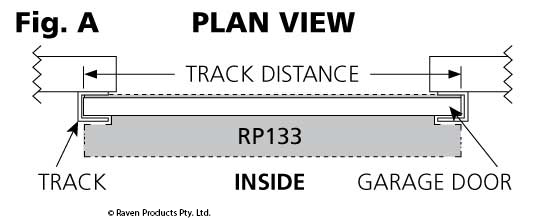

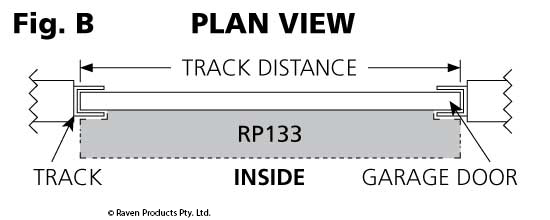

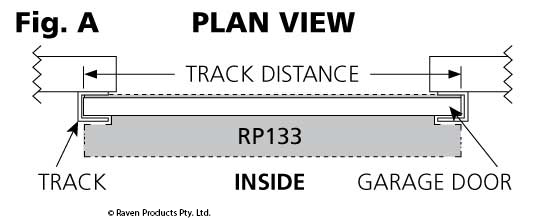

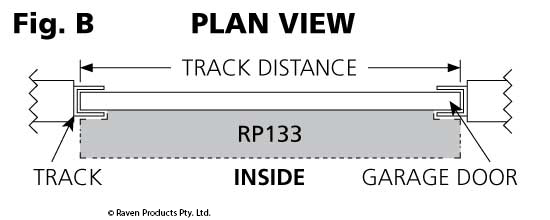

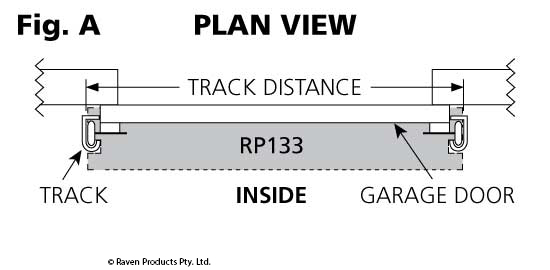

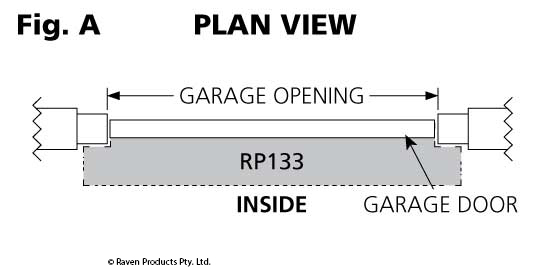

- Check garage door configuration. Refer to Fig. A or Fig. B.

- Open garage door and measure the full distance between the inside of the garage door tracks. Refer to Fig. A or Fig. B.

- Cut RP133 to marked length using a hacksaw.

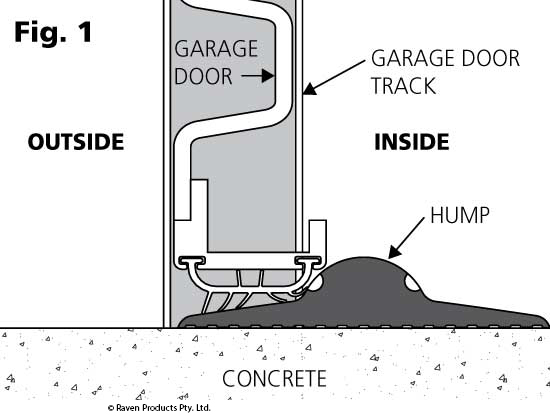

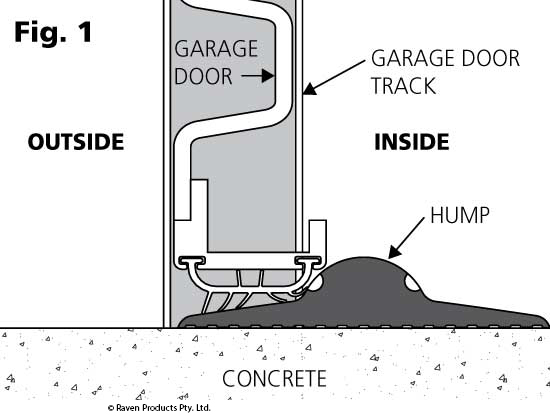

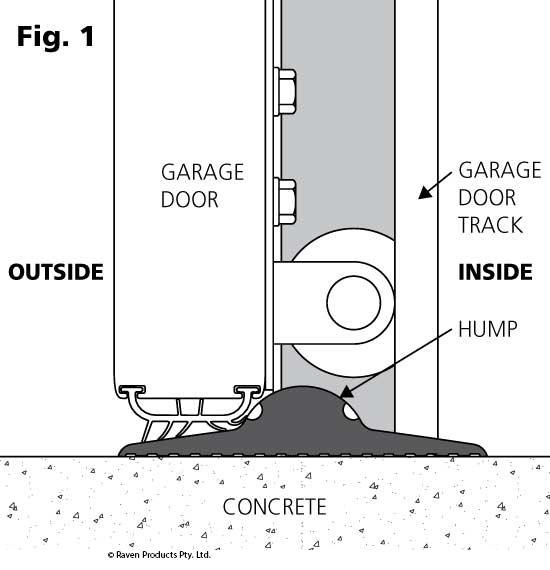

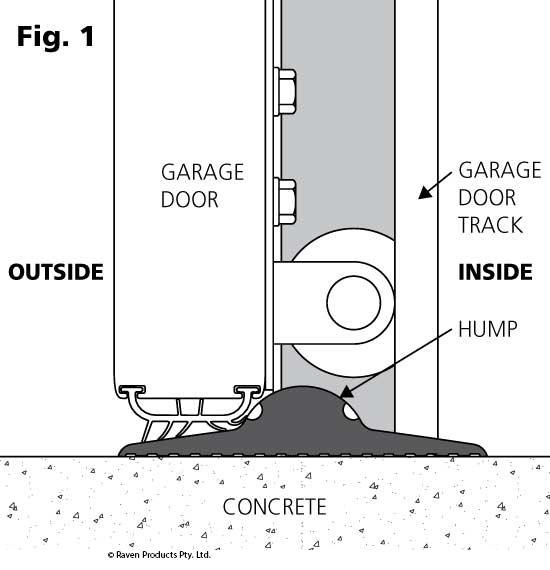

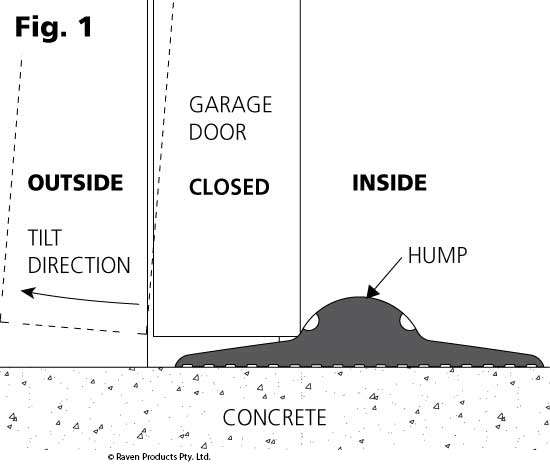

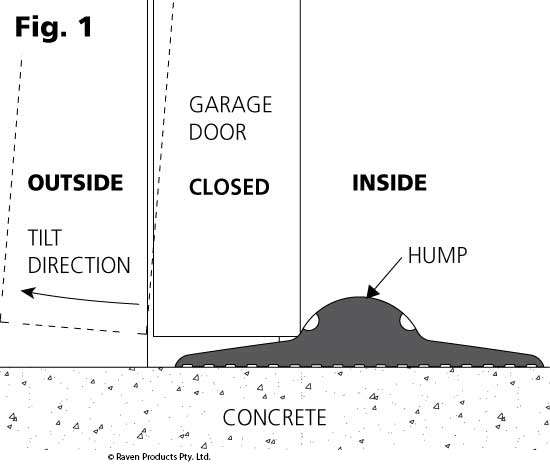

- Position RP133 so the hump is inside the garage door bottom when closed. Refer to Fig. 1.

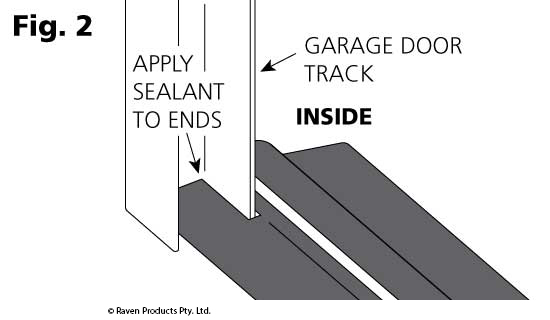

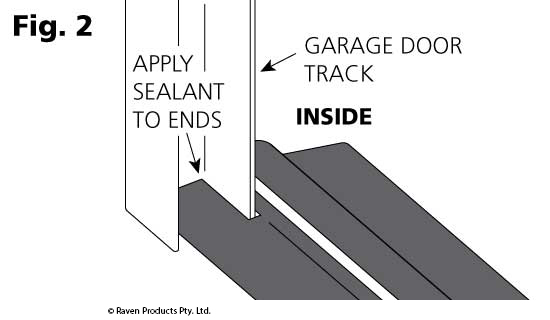

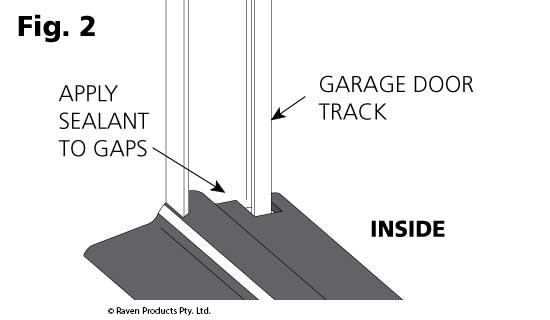

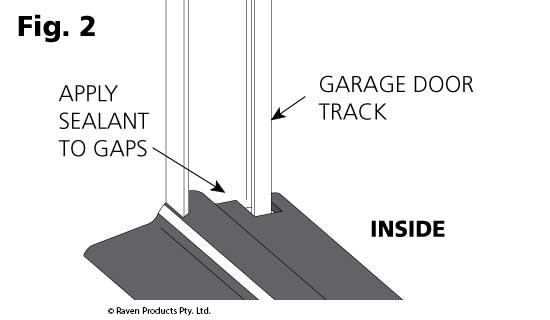

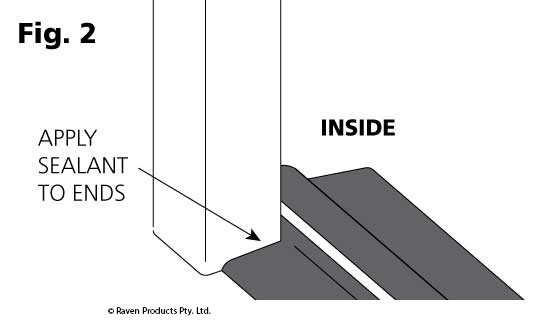

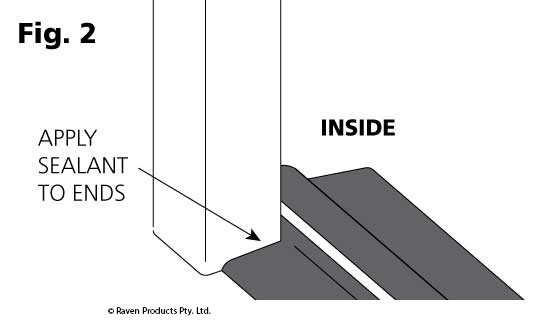

- Mark RP133 at each end where it needs to be slotted to seal neatly around the garage door track. Refer to Fig. 2. Cut the RP133 as marked.

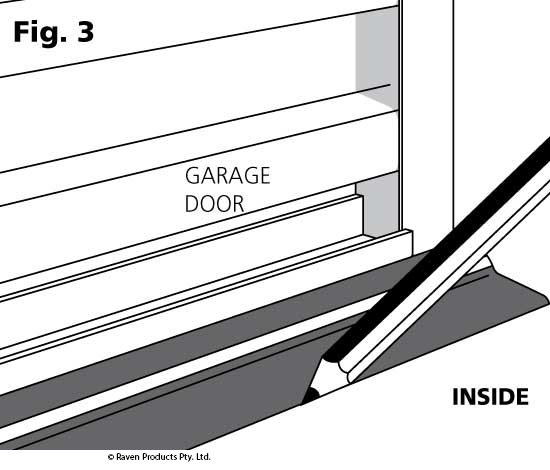

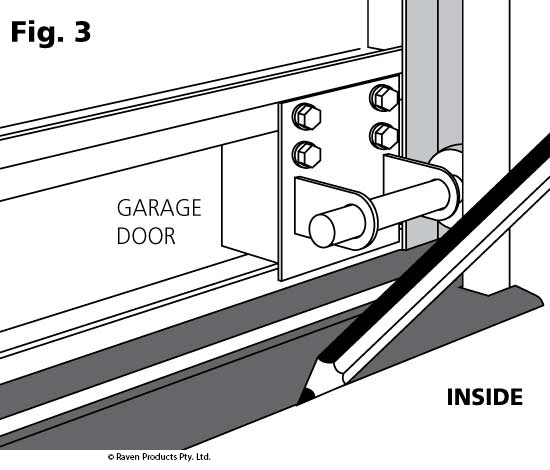

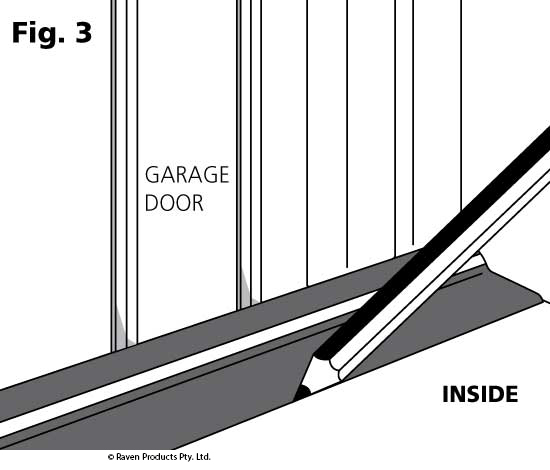

- Inside the garage with the door closed, position the RP133 as shown in Fig. 1. Mark a pencil line along the back edge of the seal on the concrete floor. Refer to Fig. 3.

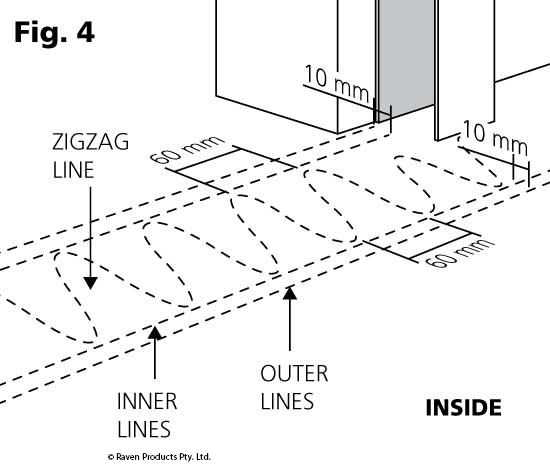

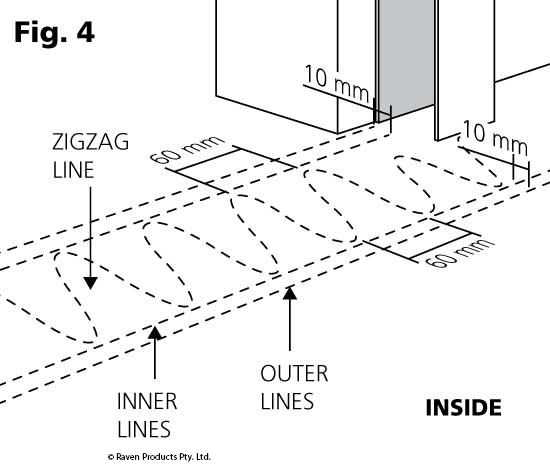

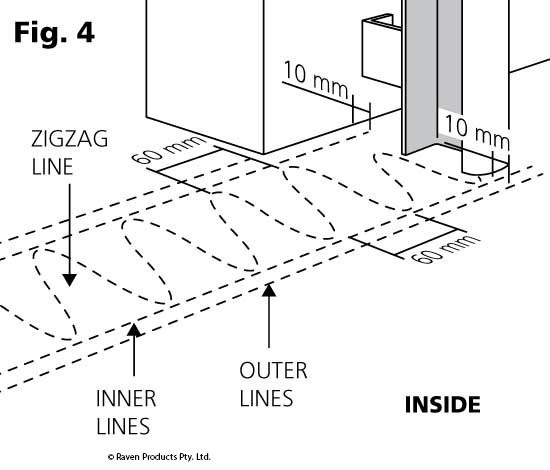

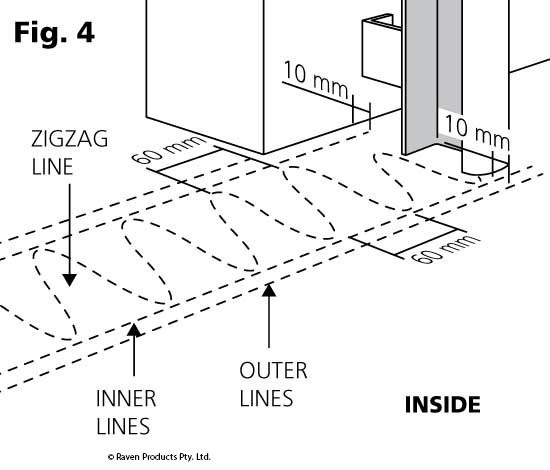

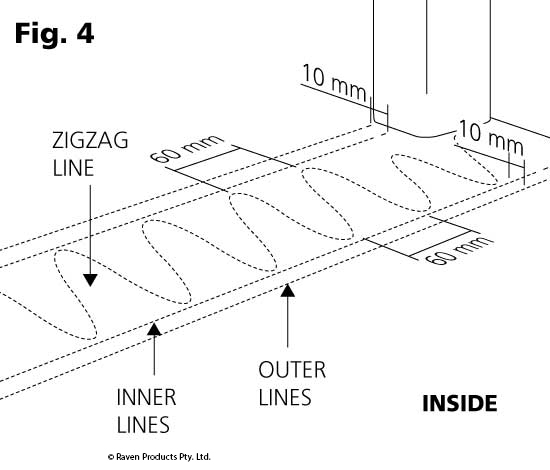

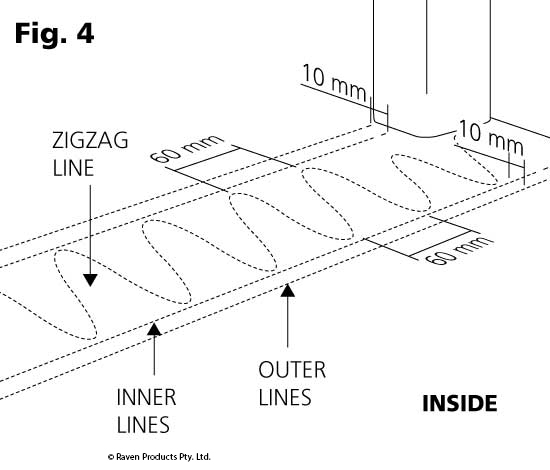

- Open the door and mark a pencil line along the outside front edge of the RP133 on the floor. Remove RP133 and pencil mark two parallel lines 10mm inside the existing marked lines. Then pencil mark a zigzag line (60mm spacing interval) in between the newly marked floor lines. Refer to Fig. 4.

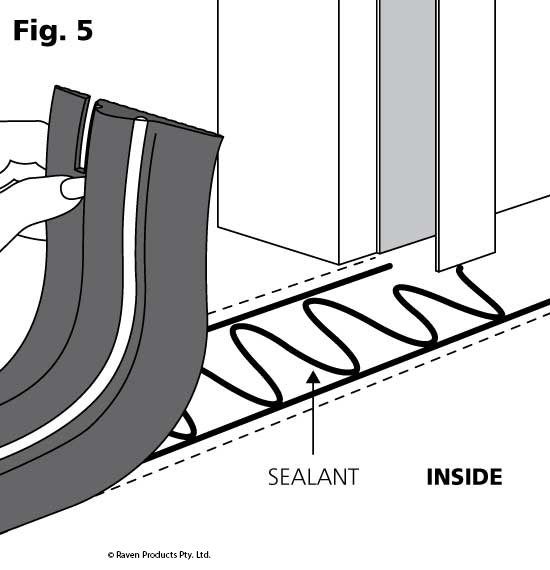

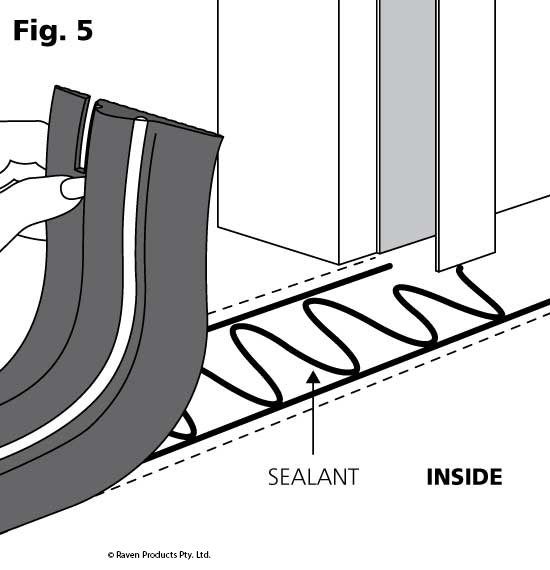

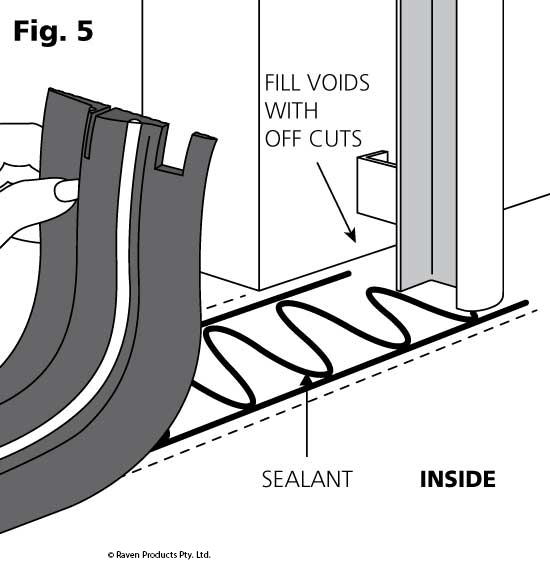

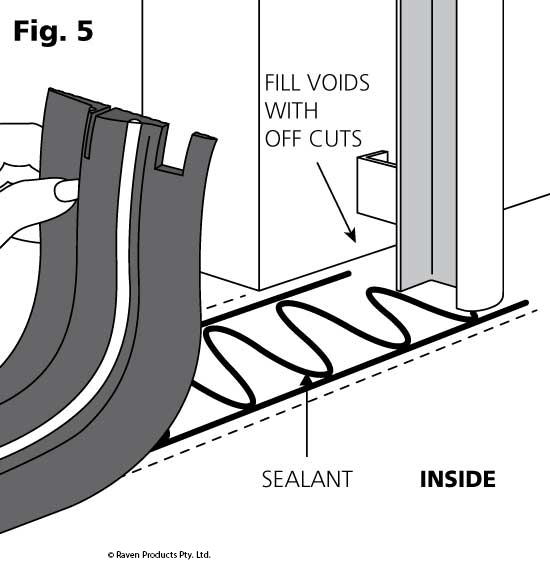

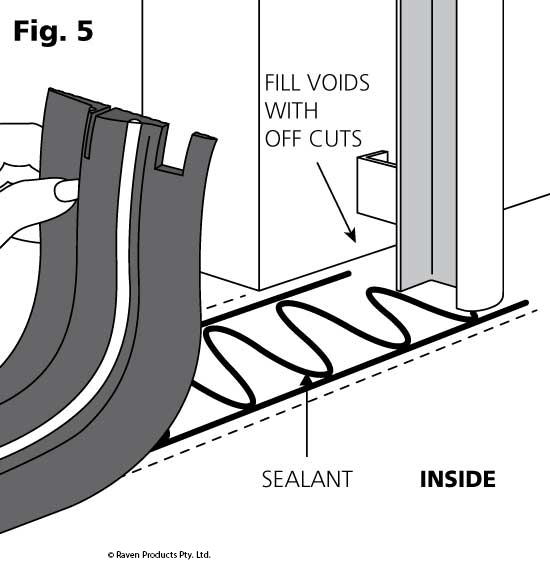

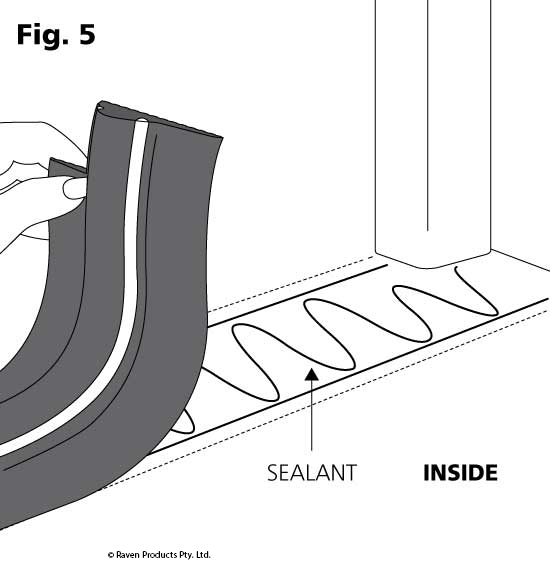

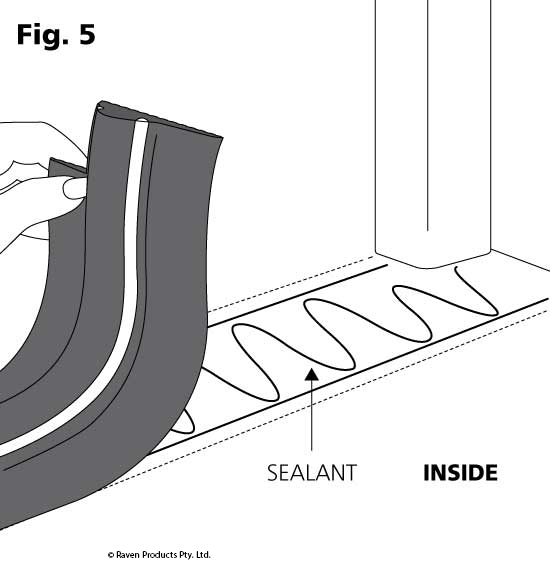

- Make sure RP133 sits flat. Refer to notes. Apply a 3mm - 5mm bead of supplied adhesive sealant to the concrete floor following the marked pencil lines but 10mm inside the outer marked lines as shown in Fig. 4 and Fig. 5.

- Beginning at one end, using the outer marked lines as a guide, progressively place RP133 onto the adhesive sealant bed by pressing down firmly on the seal and working carefully to the other end. Ensure firm pressure is applied along the full length of the RP133 to ensure a good adhesive bond between the seal and the floor surface. Refer to Fig. 5.

- Apply sealant to ends of RP133 and fill any voids. Refer to Fig. 2.

- Before adhesive cures, remove excess with a cloth. Allow 24 hours before driving over the RP133.

NOTE: Prior to installation, the concrete floor surface must be cleaned thoroughly to remove dust, oil and grease. If the floor is painted, wire brushing where the seal is to be installed will ensure best adhesion. Prior to step 7, roll out RP133 to lay flat preferably in sunlight until RP133 is level along full length. Apply suitable weights to hold RP133 flat along full length in step 8. Please refer to the door manufacturers door closer adjustment instructions before installing the RP133 threshold seal. Manual door close latching may require adjustment.

- Open garage door and measure the full distance between the inside of the garage door tracks. Refer to Fig. A.

- Cut RP133 to marked length using a hacksaw.

- Position RP133 so the hump is inside the garage door bottom when closed. Refer to Fig. 1.

- Mark RP133 at each end where it needs to be notched out to seal neatly around the garage door track. Refer to Fig. 2. Cut the RP133 as marked.

- Inside the garage with the door closed, position the RP133 as shown in Fig. 1. Mark a pencil line along the back edge of the seal on the concrete floor. Refer to Fig. 3.

- Open the door and mark a pencil line along the outside front edge of the RP133 on the floor. Remove RP133 and pencil mark two parallel lines 10mm inside the existing marked lines. Then pencil mark a zigzag line (60mm spacing interval) in between the newly marked floor lines. Refer to Fig. 4.

- Make sure RP133 sits flat. Refer to notes. Apply a 3mm - 5mm bead of supplied adhesive sealant to the concrete floor following the marked pencil lines but 10mm inside the outer marked lines as shown in Fig. 4 and Fig. 5.

- Beginning at one end, using the outer marked lines as a guide, progressively place RP133 onto the adhesive sealant bed by pressing down firmly on the seal and working carefully to the other end. Ensure firm pressure is applied along the full length of the RP133 to ensure a good adhesive bond between seal and floor surface. Refer to Fig. 5.

- To prevent leakage at ends of RP133, fill voids with off cuts and seal gaps with sealant. Refer to Fig. 2 and Fig. 5.

- Before adhesive cures, remove excess with a cloth. Allow 24 hours before driving over the RP133.

NOTE: Prior to installation, the concrete floor surface must be cleaned thoroughly to remove dust, oil and grease. If the floor is painted, wire brushing where the seal is to be installed will ensure best adhesion. Prior to step 7, roll out RP133 to lay flat preferably in sunlight until RP133 is level along full length. Apply suitable weights to hold RP133 flat along full length in step 8. Please refer to the door manufacturers door closer adjustment instructions before installing the RP133 threshold seal. Manual door close latching may require adjustment.

- Open garage door and measure the full distance of the opening plus an extra 40mm each end. Refer to Fig. A

- Cut RP133 to marked length using a hacksaw.

- Position RP133 so the hump is inside the garage door bottom when closed. Refer to Fig. 1.

- Mark RP133 at each end where it needs to be notched out to seal neatly around the wall. Refer to Fig. 2. Cut the RP133 as marked.

- Inside the garage with the door closed, position the RP133 as shown in Fig. 1. Mark a pencil line along the back edge of the seal on the concrete floor. Refer to Fig. 3.

- Open the door and mark a pencil line along the outside front edge of the RP133 on the floor. Remove RP133 and pencil mark two parallel lines 10mm inside the existing marked lines. Then pencil mark a zigzag line (60mm spacing interval) in between the newly marked floor lines. Refer to Fig. 4.

- Make sure RP133 sits flat. Refer to notes. Apply a 3mm - 5mm bead of supplied adhesive sealant to the concrete floor following the marked pencil lines but 10mm inside the outer marked lines as shown in Fig. 4 and Fig. 5.

- Beginning at one end, using the outer marked lines as a guide, progressively place RP133 onto the adhesive sealant bed by pressing down firmly on the seal and working carefully to the other end. Ensure firm pressure is applied along the full length of the RP133 to ensure a good adhesive bond between seal and floor surface. Refer to Fig. 5.

- Apply sealant to ends of RP133 and fill any voids. Refer to Fig. 2.

- Before adhesive cures, remove excess with a cloth. Allow 24 hours before driving over the RP133.